Designed for Change

By Skylar Tibbits

Active products that adapt to fit users' needs can be stronger, cheaper, and more comfortable than traditional, static objects.

Active products that adapt to fit users' needs can be stronger, cheaper, and more comfortable than traditional, static objects.

Most products, just like pieces of infrastructure and much of the humanmade world around us, have one thing in common: They are designed to be stable and static. They are engineered to fight against all the forces around them—gravity, vibration, temperature, moisture, and so on. They are designed to be robust. They are generally not designed to be lean and adaptive, or flexible, or reconfigurable. Today’s products often don’t take advantage of their material properties and aren’t programmed to have any of the lifelike qualities that are possible with active matter.

We compensate for the lack of adaptability or lifelike qualities in our products by creating so-called smart versions of them: smart thermostats, smart clothing, smart shoes, smart cars, and even smart bassinets that sense babies’ sleep patterns and adapt the sounds or motion accordingly. These smart products are often more expensive, heavier, and more complicated to build. They become easier to break and more difficult to use, and they consume more power.

Our goal should be to make active products, by which I mean products, objects, or materials that can move, reconfigure, transform, assemble themselves, or adapt to their surroundings. To achieve active products, we need to reconsider the way we think and talk about our (statically designed) world.

Self-Assembly Lab, MIT/Google

One of the fundamental principles of engineering has always been that any product or system ought to be designed to resist the forces that may lead to its destruction—in other words, designing for robustness in the traditional sense. The result is that systems tend to be overengineered, and intentionally so. For example, various safety factors exist in buildings, bridges, cars, or planes to ensure that structures will withstand more than the weight we anticipate they will bear. Of course, this principle is extremely important for safety. But from a materials perspective, it’s wasteful.

Perhaps it’s time that we rethink or expand what we mean by robust—and redefine smart in the process, too. A structure that is robust could also be active, lean, adaptable, and error correcting. A number of researchers have built morphing, self-adapting bridges and slab structures that can change dynamically as load is applied. These structures, although currently built electromechanically, demonstrate extremely lightweight and more materially efficient structures that can span and cantilever significant distances. They are one step closer to this dream of higher-performing structures with minimal materials while adapting to complex dynamic situations—without more components, more material, or more rigidity. In the end, less is smart: The more we can do with less, the smarter our systems will become.

The principle of error correction is critical to creating active products and structures. It allows us to ensure that accurate products are assembled in the factory, and it can also inspire us to design structures that improve over time. We can actively engage, enhance, and make the most of this principle. The challenge is to figure out how to design for error correction in the products around us.

We can start by looking for timeless design and material functionalities. Think of classic furniture, vintage cameras, or classic cars: The designs of these products have lasted through time and often still look as radical yet elegant today as they once did. Materials and functionality can last as well—and even get better. Concrete, counterintuitively, is a material that can grow stronger with age due to the hydration process and interaction of the material elements. We can imagine designing systems of all sorts—manufacturing, products, or environments—where we impart energy and just the right conditions to promote error correction and overall improvement over time.

Natural systems exhibit characteristics of robustness and resilience—they are lean, soft, and agile, and can adapt to changes in their environment. These systems resist failure very differently compared with the ways we typically engineer systems. For example, bone grows with variable density and stiffness depending on its location in the body and the weight an individual carries. An astronaut’s bones will adapt and reduce their mass, and then regrow when they get back to Earth. Many natural systems, including our bodies, can regrow, adapt, and correct errors when needed. In other words, error correction itself is a form of robustness.

To understand how error correction can work in everyday objects, let’s look at the simple example of building a circle. One manufacturing approach is to make the components with extreme precision, with the exact angle needed for the exact number of parts. If you start to connect the parts with rigid and strong connections, you will need to build in some error tolerance. If the weather changes, or the moisture or temperature increases, the parts may become slightly larger or smaller than originally designed. The machine that was used to fabricate them and the materials themselves all have some amount of error tolerance. If you have just a few components, it might work. But as you increase the number of parts, tolerance propagates, and it is likely that the last part won’t fit perfectly. Even if the parts fit or can be forced together, fluctuations in the environment may create differential expansion or contraction, causing the circle to buckle or bulge. Every piece has only one place in the finished circle, and each one needs to be made with 100 percent precision to create the perfect circle.

The jammed rocks and string behaved like a solid structure, but once we removed the top and bottom plates, it instantly dissolved, which meant that we could switch the structure on or off at any time.

A second approach is to build each part so it can pivot or flex where it meets the neighboring part—building error correction into the system. With flexible connections, as the parts of the circle come together, they adjust to one another. As the last part goes into the circle, all of the others can adjust their angles to create perfection. Adding simple flexibility in the connections allows the circle to find its own equilibrium. When the environment fluctuates, these units will adapt and adjust, always maintaining the perfect circle. Flexibility serves as a form of error correction that provides us with more robust structures without adding more material or complexity to the design.

Similarly, when we are assembling something with bolts, we are often told not to overtighten the first bolt. Rather, we hand-tighten all of the bolts and then go back around and tighten the rest. This process ensures that all of the bolts are tightened evenly and are well aligned. Or when bolting a tire onto a car, it is recommended to follow a star pattern of tightening to ensure that the tire sits perfectly snug. If you overtighten one side substantially more than the other, then the initial side will be tightened off-axis. These simple techniques allow structures to have some flexibility and to self-align, falling perfectly in place without measurement or precise machines.

In my role as the founder and codirector of the Massachusetts Institute of Technology’s Self-Assembly Lab, I often strive for less material and less complexity in our designs, but there is also a case for material redundancy if we view the term in a different light. If you have more material than necessary, you can sometimes create a very simple system that may be fast, inexpensive, and easy to build. Think of a bird’s nest—it can be expediently assembled, often with a lack of precision. The geometric intricacy of the nest can be robust and create breathability and flexibility—features that a more rigid structure may not achieve. So we can sometimes counteract a lack of efficiency in material usage if we can increase speed, improve material placement, and decrease cost by using simple and imprecise components to create a robust and adaptable structure.

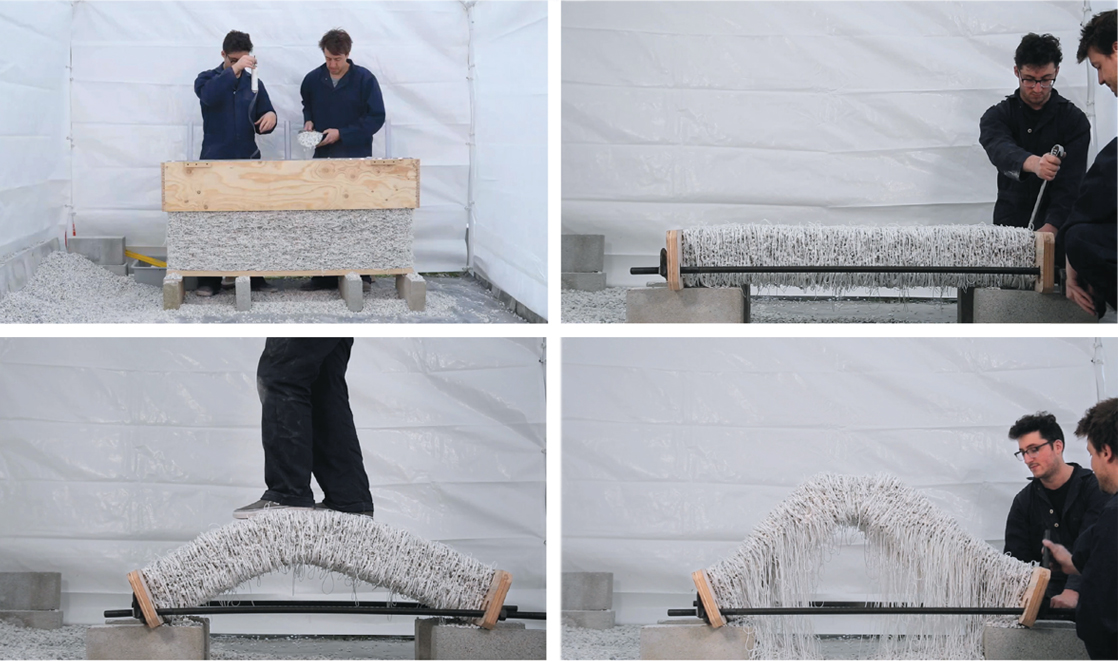

The Self-Assembly Lab in collaboration with Gramazio Kohler Research at ETH Zurich developed a project that highlights this principle of material redundancy and adaptability: a system of granular jamming that uses rocks and string to create load-bearing columns or walls. Granular jamming is a material phenomenon that allows disordered particles to transition from a liquid-like state into a solid-like state and back again. Think of coffee in a vacuum-sealed package: That package is typically very stiff and feels like a rock. But when you open the package, the coffee easily flows out. We took advantage of this principle; however, we developed a granular jamming system that doesn’t require a vacuum or a membrane. Given that membranes are susceptible to puncturing and vacuums are energy intensive, we wanted to find a new technique for granular jamming that could be used as a construction method.

In order to build the jammed structure, we created an elegant balance of forces by depositing the right mix of loose rock and continuous string, layer by layer, within a bounding box. After a layer of rock was poured into the box, a robot unspooled a series of loops of string, then another layer of rocks, then string, and so on. When we removed the bounding box, only the rocks that were near the string got stuck, while the rest of the rocks fell away. The rocks couldn’t go anywhere when the bounding box was removed because the rocks took the compressive forces, and the string took the tensile forces, which made the structure jam into a solid object. This technique creates a load-bearing structure without using structural members, connectors, adhesives, or other binders.

Self-Assembly Lab, MIT/Mechanics of Slender Structures Lab, Boston University

Our most recent approach to this research advanced our goal of letting the material do the work, making it as easy and fast as possible to build. In this latest version, we used a simple unspooling technique whereby a spool of string uncoils itself into perfect circles, the size of which depend on the spool and its height above the ground. This method uses off-the-shelf spools of string and replaces the precise robot deposition with a simple principle of physics: Let the string make precise patterns on its own. We then simply poured the rocks and unspooled the string to make columns and walls.

Through granular jamming, structures can actually become stronger with load because the rock and string increasingly act more like a solid. We realized that if we used a top and bottom plate and compressed the structure with a threaded rod, we could jam it into solid structural components and move them around. We built a column and then rotated it into a beam or a bridge, as well as a wall that we rotated into a slab, and then we walked across the beam and slab structures. The jammed rocks and string behaved like a solid structure, but once we removed the top and bottom plates, it instantly dissolved, which meant that we could switch the structure on or off at any time. We could build these structures extremely fast, make them load bearing, and then instantly switch them off, so they fall away into a pile of rocks and string.

Going one step further, we realized that if we continuously compressed the horizontal beam, it would start to morph, like a semisolid material, into an arch, which we walked across and loaded at various points. This exploration showed us the fascinating and strange ways that simple materials like rocks and string can behave: They can act like solids, semisolids, liquids, and even switchable devices with reversible properties. We can make extremely strong structures with minimal construction time, or soft structures that can be sculpted into shape.

Each of these granular jamming techniques works only because of the redundancy of the material system. Because it’s not feasible to place and position every single rock (there were hundreds of thousands of rocks in the experiment), we can’t be certain that the connection of the rocks or the location of the fiber is perfect. We can, however, employ rock and fiber in just the right amounts to ensure the stability of the structure. This type of redundancy can also make a robust system, even though we have very little control over the precision or the details.

So rather than robustness being about more control and attempting to fight the forces of failure, as is the typical case with a structural beam or component, robustness can also be achieved through expedience of construction, and more materials yet less control over their placement. In this way, the system is working in harmony with the forces of compression and tension to get stronger. We are certainly using more material than necessary, but the construction process is far faster than if it involved manual placement or poured concrete. In other words, we can sometimes gain speed or performance by letting go of control in the process.

With material capabilities and fabrication processes advancing rapidly, research teams are increasingly demonstrating a new class of products that are no longer static and passive. At the Self-Assembly Lab, we have created a number of examples of active products, such as a flat wooden sheet that jumps into a table, assembling itself from its flat-packed box; a shoe that forms itself, eliminating molding or manual forming in the factory; and a knit garment that adapts to the shape of the body and changes porosity and thickness to keep you comfortable in any environment.

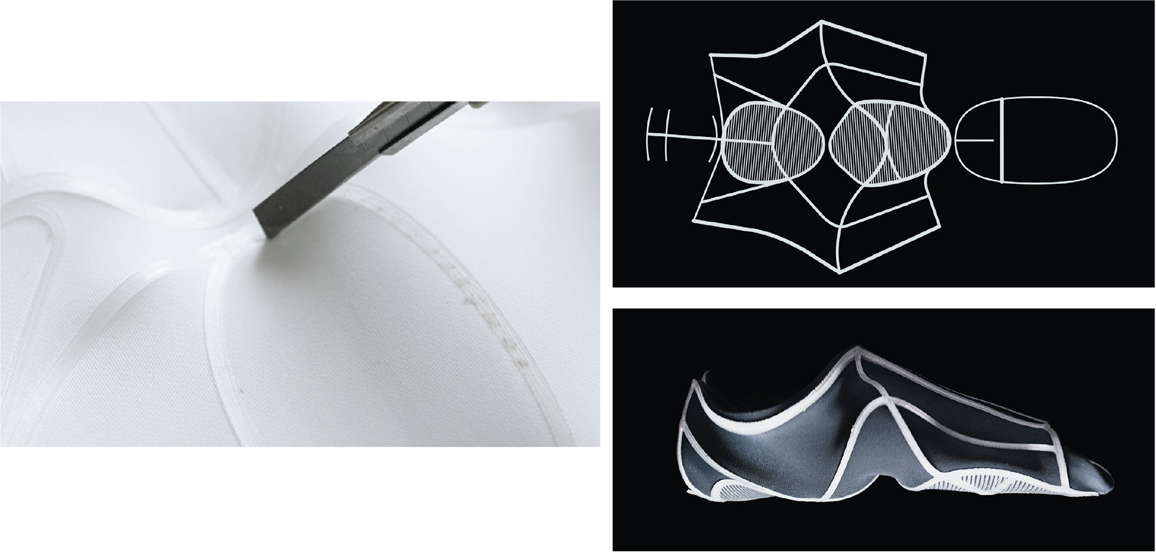

Underlying many of these examples is a technique we developed for transforming flat sheets into three-dimensional shapes. To do this, a piece of stretchable textile, such as Lycra, is initially pulled tight and wrapped around a plate. The prestretching process embeds and stores energy in the material, to be released later on. The pattern of stretch can also bias the final transformation. For example, if the textile is stretched in a uniform manner, it will shrink uniformly when released. If the textile is stretched more in one direction, however, it will undergo a greater shrinkage force in that direction when it is released. After stretching the textile, we add rigid or flexible material layers, such as nylon, on top of it. These layers embed the geometric information and pattern that will direct the precise transformation of the shape.

The textile instantly jumped into its 3D shape, encoded with the shoe’s curvature to self-form into a foot-like shape.

The type of material, the thickness of the layer, and the 2D or 3D pattern placed onto the textile all influence how it behaves next. If the material is rigid or thick, the layer will likely have greater force than the shrinkage of the stretch textile, and it will significantly constrain the material from transforming. To take advantage of the stretch textile force, the deposited layer can be flexible or thin in certain areas to add flexibility and allow for the 3D transformation.

The 2D and 3D shape of the deposited layer also influences the pattern of transformation. For example, if you deposit a circle onto the textile and stretch the textile in a uniform way, then when you release it from the rigid plate, it will jump into a saddle-like shape called a hyperbolic surface. The pattern of the material can be used as a geometric code to promote complex surface transformations. This technique triggers the precise self-forming process, transforming an ordinary flat sheet of textile into a useful shape.

We recently applied this technique to developing active shoes. Traditional shoe manufacturing is an example of an industry that produces static objects by manually assembling different parts: the uppers, insoles, outsoles, and other components. If we consider just the uppers, for example, there are usually quite a few components, such as the vamp, the outside quarter, the inside quarter, the strap, and more. Each of these components requires a significant amount of manual labor to assemble. The components need to be die-cut or laser-cut from leather or other materials. This cutting is one of the most complex and labor-intensive aspects throughout the entire process. If the shoe is going to be made out of leather, the parts need to be arranged on a piece of leather, keeping in mind that the right and left shoe need to go together. Natural leather has a different amount of stretch across the different regions of the piece, which means that the various components of the shoe require a skilled hand for precise placement in order to meet all of the stretch requirements.

After carefully cutting the components, someone needs to form, sew, glue, and assemble them. This process can take many people, many machines, and many minutes, depending on the complexity of the material and the shoe. The manufacturing of shoes is still today mostly a manual process even for the largest and most technologically sophisticated companies. Similarly, the design process is traditionally separate from the fabrication and manufacturing process. Even in the most recent advances of 3D industrial knitting for shoe uppers, such as Nike’s Flyknits, the final product is designed to be static, it is not customized to the user, and it requires manual bonding or assembly for the sole of the shoe. Only recently have design and manufacturing started to inform one another and blur the lines between conception and creation with active materials.

Active shoes spring from a single, two-dimensional sheet into functional footwear. A piece of fabric is stretched taut and then printed with material of various thicknesses (above left) in a specific pattern (above right). When the fabric is released, it folds and curls into a shoe (bottom right). This process eliminates the many pieces and specialized skills normally required to make shoes.

Christophe Guberan/Carlo Clopath/Self-Assembly Lab, MIT

The process of manually forming shoes is precisely what we targeted in a collaboration between our lab and product designers Christophe Guberan and Carlo Clopath. We wanted to see how we could simplify the assembly process by taking advantage of material transformations. To design an actively self-forming shoe, we had to identify the geometric code that we would print onto the stretched textile that would allow it to transform into a shoe. First, we stretched the elastic textile around a rigid plate in a uniform manner. We then printed a polymer onto the stretched textile in a specific pattern. The textile was stretched in a uniform manner, and the material properties were kept constant while the design variable that we adjusted was the printed pattern. The printing process allows for custom patterns and complete control over the shape while testing it out; once a shape is defined, it can be laminated, bonded, sewn, or otherwise combined with the textile.

We designed the printed pattern to create all of the curvature of today’s shoes with a single piece of textile wrapping the foot from the toe to the heel. We went through many iterations and tested patterns to promote the precise transformation. Ultimately, we identified a pattern, printed it onto the textile, and released it from the plate. The textile instantly jumped into its 3D shape, encoded with the shoe’s curvature to self-form into a foot-like shape. As an extension of this process, we also created the sole of the shoe by promoting further curvature and wrapping from the bottom up around the sides.

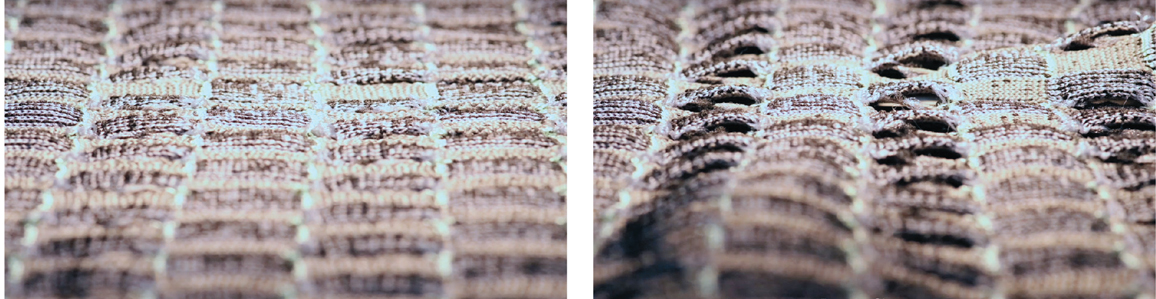

Recently, we looked at the adaptability of our textiles to address changing functionality or comfort requirements while the product is in use. We wanted to go beyond just the shape change of a textile and create porosity change, with new functionality built directly into the textile from the filaments, fibers, and yarns all the way up to the garment. To accomplish this goal we worked in collaboration with the clothing company Ministry of Supply and other researchers on a project through an organization called Advanced Functional Fabrics of America.

Self-Assembly Lab, MIT/Ministry of Supply/Hills Inc./Mechanosynthesis Group, MIT/Iowa State University

The first development was focused on a single-direction transformation, where the textile could transform only once and never again. This type of transformation was geared toward tailoring and creating customized products that fit an individual’s body. Typically, tailoring is only possible either by manufacturing a custom garment, which is often logistically complicated, expensive, and slow, or by manually cutting and sewing in a traditional tailoring process, which is often labor intensive and expensive. For these two reasons, mass-produced garments use standard sizes—such as small, medium, large, and extra-large—that don’t fit any individual perfectly. Similarly, even the same product and same size can be completely different depending on what factory it came from. With our research, we showed that we could still mass-produce garments, taking advantage of the speed, scale, and efficiency of industrial knit textile manufacturing, yet we could activate garments to self-transform around the customer.

By changing the materials in relation to one another, we can finely tune their various properties, designing them to expand or contract based on external temperature or moisture changes.

There are a number of examples where companies are trying to mass customize textile products using industrial knitting, either flatbed knitting or circular knitting. The dream is that you can go from a 3D body scan of the customer, and then directly manufacture a unique garment and ship it to the customer’s door. This process is extremely challenging logistically, however, because the custom program to run the knitting machine is not automated and because of the lack of dimensional precision in textile manufacturing, which makes this an unsolved problem.

Our approach was to avoid the custom program and custom manufacturing challenges and focus on embedding the customization intelligence directly into the textile, not the machine. This shift allows us to mass-produce standard-sized garments, but when they arrive at the store, the garment can be activated with heat or moisture and will then transform itself, adjusting directly to the customer’s body. In this way, the customer receives a uniquely tailored garment that fits perfectly, without the complexity and cost of custom manufacturing or cut-and-sew tailoring. This type of single-direction transformation will happen only once; the garment will not return to the original shape and won’t transform accidentally when the customer wears or washes it. It is only designed to adapt for their perfect fit.

In the more recent developments of this research, however, we have been able to demonstrate reversible, bidirectional transformations of textiles that are designed more for climate adaptability, allowing the textile to transform based on fluctuations in the external environment or the customer’s body temperature. These approaches also utilize industrial knitting technologies where we can swap the fiber, filament, or yarns, on a stitch-by-stitch basis, across the entire garment. That means, much like multimaterial 3D printing, we can change materials at every “pixel” (which in this case is a stitch in the textile) in a 3D garment.

Self-Assembly Lab, MIT/Ministry of Supply

By changing the materials in relation to one another, we can finely tune the various material properties, designing them to expand or contract based on external temperature or moisture changes. Natural materials such as wool or various polymer fibers will shrink with a certain temperature or moisture activation. We can then vary the knit structure, stitch by stitch, across the garment to change the way that the textile will move. A contracting zone can pull open certain pores, or lift a vent flap to adjust breathability. Some fibers will shrink, while others will bulk and expand in cross section. We can use these behaviors to transform the global shape of the garment, creating zones that are thicker or thinner for insulation, comfort, breathability, or better fit.

With this development, we can create knit textile garments that adapt for thermal comfort: If someone walks from their warm and cozy house into the brisk, cold outdoors, their lightweight and breathable sweater can close its pores and get thicker to help insulate and warm their body. Or vice versa, if they are in a cool air-conditioned office and they walk outside on a hot summer day, their garment should be able to open up and become more breathable and thinner, more lightweight, to help cool their body and keep them comfortable in both temperature extremes. This type of active, self-transforming textile garment is bidirectional and can continuously adapt, going back and forth, adjusting to the ever-changing temperature dynamics that we experience every day.

Self-forming footwear and active textiles offer new perspectives on the agency of our materials, arguing for a more dynamic and ever-changing performance relationship with our products. Although some of these products currently exist only in the lab, not on the market, that is likely not because they are more difficult to produce or more expensive or less durable. Their scope is limited today mainly because manufacturers and consumer cultures haven’t yet made room for thinking about active products in this new way. But that will eventually change.

These materials, unlike the static products of our everyday world, do not resist all forces; instead, they become highly active, take advantage of the forces around them, and make use of their inherent material properties. Products shouldn’t sit around passively—they should adapt to our needs, react to the environment, and push us to perform better and live healthier lives together.

This article is adapted from Things Fall Together: A Guide to the New Materials Revolution by Skylar Tibbits, copyright 2021 by Skylar Tibbits. Reprinted by permission of Princeton University Press.

Click "American Scientist" to access home page

American Scientist Comments and Discussion

To discuss our articles or comment on them, please share them and tag American Scientist on social media platforms. Here are links to our profiles on Twitter, Facebook, and LinkedIn.

If we re-share your post, we will moderate comments/discussion following our comments policy.