Pulling On the Shade

By Fenella Saunders

Transparent, liquid-filled films become opaque when stretched.

Transparent, liquid-filled films become opaque when stretched.

DOI: 10.1511/2013.104.326

You are surrounded by single-purpose objects: a table that is only a table, a shirt that provides only one level of warmth, a window that always admits the same amount of light. But there is no reason fabricated materials should not be able to switch their properties on and off the way biological materials often do, such as the eye adjusting its sensitivity to light or hairs standing up on the skin in the cold. “To make materials that are dynamic and responsive is the future of materials science,” says Joanna Aizenberg, a materials engineer at Harvard University.

Aizenberg started down this path while brainstorming one day with a group of colleagues. As they were talking about future directions for their field, they jotted down an idea: Is it possible to create a tent out of a water-repellant fabric that could be transparent on rainy days but reflective when it is sunny? As Aizenberg and her colleagues reported in the journal Nature Materials, they have created a hybrid liquid-solid material that can perform this optical shift simply by being stretched.

Image courtesy of Joanna Aizenberg.

The researchers began by working with a woven polymer material, which can stretch and then return to its original shape. They coated this fabric with a thin layer of lubricant that has a particular affinity for the fabric, so it does not rub off or evaporate easily. The lubricant also repels water, ice, dust, oil, and many other contaminants.

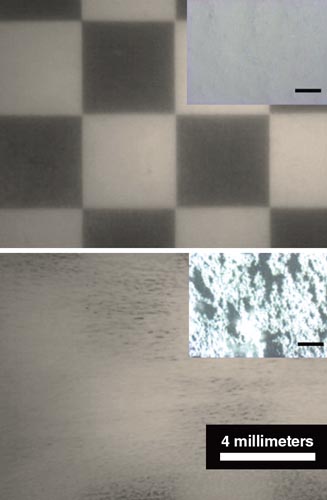

On the unstretched fabric, the lubricant forms a coating that is perfect down to the atomic level. “It’s kind of counterintuitive but we use rough surfaces to hold the liquid and create molecularly smooth surfaces,” Aizenberg says. “There are no defects to hold onto, and liquid after all is movable anyway. Everything that touches these surfaces just slides off.” In addition, any incoming light has nothing to scatter off of, so the material is transparent.

When the fabric is stretched, the pore size between fibers expands and some of the liquid recedes into them. At that point, the liquid surface becomes uneven; light scatters from it, turning it opaque; and the material no longer repels water. When the fabric is released, it becomes smooth again and its previous properties return.

To scale up their test-size material to something like a tent, real-world conditions have to be considered. Although the lubricant is persistent, the material still needs a replenishing reservoir for long-term durability. As Aizenberg explains, the lubricant would be able to restore its levels automatically, much like a wick draws up fuel in an oil lamp. Besides selecting liquids that have a low evaporation rate, Aizenberg and her team are also able to engineer ones that don’t have environmental or health concerns.

But tents aren’t the only use for such “tunable” fabrics. Instead, for instance, the substrate could be used to control the flow of liquids on its surface. Such properties may make it useful in lab-on-a-chip devices, where small quantities of fluids are put through a multitude of reactions in parallel. The materials don’t have to be stretched en masse to work—they can be bent or poked to locally alter their properties. Aizenberg and her team demonstrated that a drop sliding down the surface can be made to move at a specific speed or stopped at will by stretching specific points in the fabric.

“That creates a way of programming the velocity of the liquids moving through this device,” Aizenberg says. “I don’t need a valve, I can take my channel and stretch it, and it stops the liquid completely.” In addition, materials with different surface properties will move at variable speeds on the same surface, so it would be possible to automatically sort and identify droplets by type.

Aizenberg points out that although this demonstration shows materials controlled by stretching, other mechanisms can be used to alter the properties, including chemical, magnetic, or electrical means. “There is a whole range of other stimuli that can change the porosity of your system,” she says. “There are polymers that in response even to the environment would swell and contract and therefore make the holes larger or smaller.”

The most intriguing aspect of Aizenberg’s approach is that it could lead to dynamic materials with multiple functions. For instance, a gel that can chemically self-regulate and maintain, say, a set pH in response to temperature, without any external power, would be key for medical implants. “It’s not only black and white, it’s all of the range of properties that you can finely tune by changing the material design,” she says. “I truly think that’s where materials science is going to move.”

Click "American Scientist" to access home page

American Scientist Comments and Discussion

To discuss our articles or comment on them, please share them and tag American Scientist on social media platforms. Here are links to our profiles on Twitter, Facebook, and LinkedIn.

If we re-share your post, we will moderate comments/discussion following our comments policy.